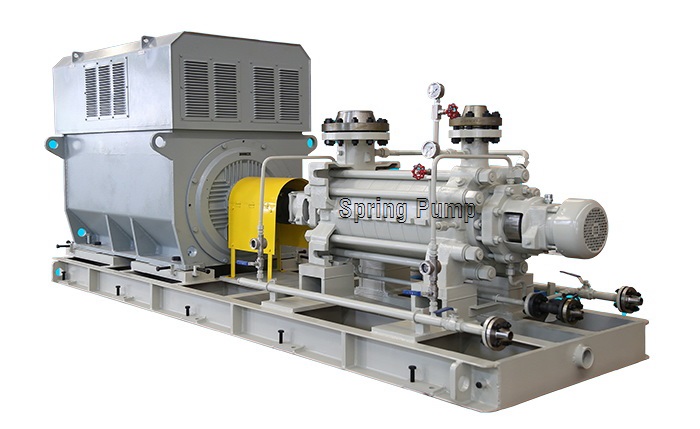

★Design:

All parts and components of the SPBB4 series pumps are designed as interchangeable standard parts, which greatly helps to reduce the storage of spare parts.

Intermediate Casing

O-rings are designed between intermediate casings when connecting the sections with tie-bolts. Metal gaskets may also be used to replace the O-rings in case of necessity.

Suction and discharge casings are normally supported with feet construction. However, center supports are used for SPBB4 150, as well as SPBB4 80 and SPBB4 100 when working temperature exceeds 150℃.

Hydraulic Model and Balancing of Axial Force

Two different hydraulic models (Impellers and diffusers) are designed for each model to expand the operating range with high efficiency. Replaceable wear rings are adopted for sealing between impeller and casing.

Most of the axial forces shall be balanced by hydraulic balancing device (drum) and the residual force shall be borne by thrust t bearings.

All SPBB4 pumps are oil lubricated, except SPBB4 25 which is lubricated with grease.

★Performance Data:

Capacity: Up to 500m3/hr

Head: Up to 1200m

Operating Press.: Up to 15MPa

Operating Temp.: -80 ~ +180℃

★Applications:

Water supply, Thermal power plant, Pipeline pressure boosting, Refrigeration project

★Flanges

Discharge flanges and suction flanges of center supported pumps are designed as vertical up, while suction flanges for foot supported pumps can be arranged in any direction.

★Shaft Sealing

In general, balanced type mechanical seals shall be used for shaft sealing. Soft packing is also applicable if necessary.

Shaft seal shall only bear as much as the suction pressure because discharge pressure shall be reduce after passing through the balancing drum.

Packing gland shall be cooled in case the temperature of flushing liquid is higher than 110℃. And the whole packing box shall be cooled if the temperature of flushing liquid is higher than 130℃

★Driving End & Rotation

Driving end of the pump is designed at the suction side and CW rotation shall be viewed from the driving end.